THE GENESIS OF A PIPE —

Dive deep into the process of turning high-grade briar into a lasting legacy.

How it all begins. —

About Briar

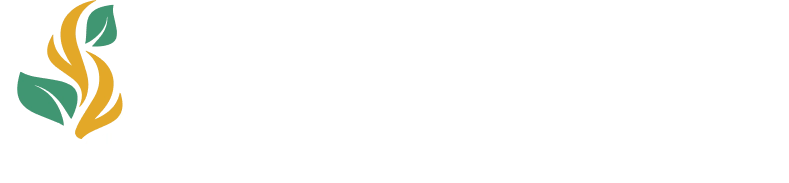

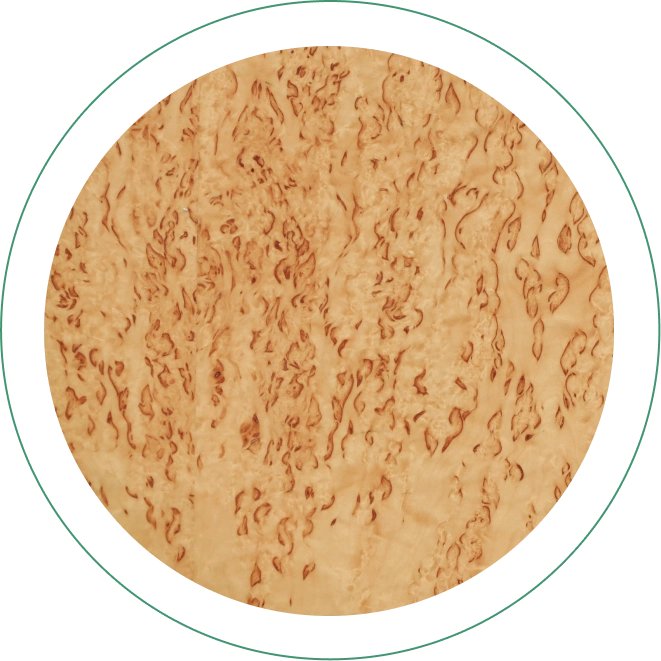

Briar is the burl wood of the white heath tree, commonly found in the Mediterranean, particularly Italy and France. The grain within these trees often contains inclusions of dormant buds, resulting in outgrowths (or burls) with a unique and high-value grain pattern.

Briar is also sturdy – and more importantly, flame-resistant – making it the ideal material for a tobacco pipe.

How it’s sourced

Because of its unique qualities, and in order to get the optimal grain, briar root must be cut by trained professionals known as briar cutters.

Refining and storing.

Once the briar root is removed from the tree, it is cut into workable blocks known as ebauchons. During this process, any imperfections are removed, and unusable blocks discarded.

To determine the value and quality of an ebauchon, blocks are expertly graded according to their grain.

Ebauchons are then boiled in water, clearing them of any remaining organic matter, and stored in specialized drying sheds for up to 8 months.

Distribution.

There are a variety of ways that artisans are able to source briar root for tobacco pipe crafting. Most distributors sell the material according to grade, as well as grain characteristics.

creating the pipe

Craft and workmanship. —

Because a defining characteristic of briar root is the inclusion of the white heath tree’s dormant buds, no two ebauchons are alike – making the resulting tobacco pipe a completely unique product.

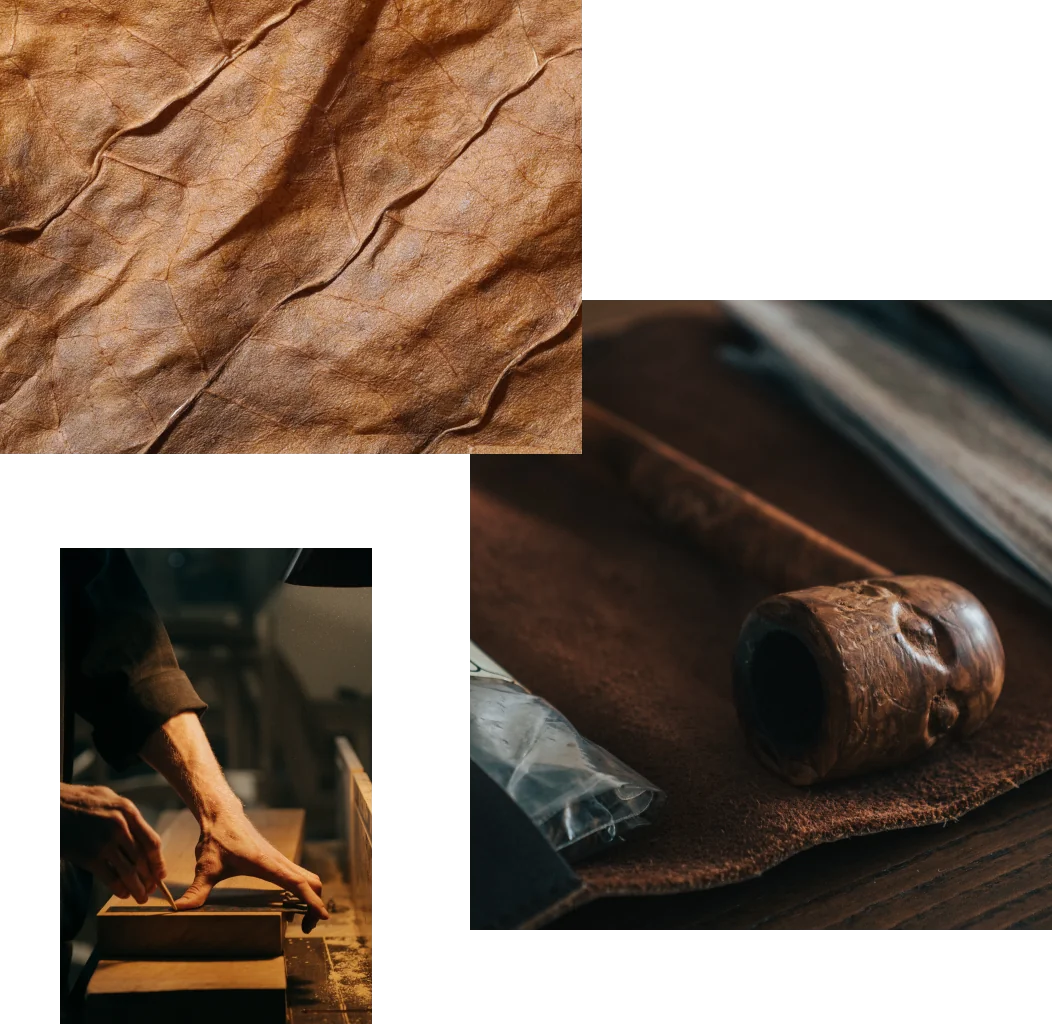

Artisans can choose to craft their tobacco pipe with handwork or lathe work, in combination with sandblasting, rustication, and hand sanding until the stummel of the pipe takes form.

Let’s break it down to the basics.

Sourcing.

Briar wood is sourced by a specially trained group of people from a specific type of tree, often found in the Mediterranean.

Refining.

The briar is refined into workable blocks known as ebauchons, boiled, and stored in drying sheds for up to 8 months.

Creating.

Artisans carefully select their ebauchons and craft them into unique tobacco pipes to be enjoyed by hobbyists all over the world.

Sourcing.

Briar wood is sourced by a specially trained group of people from a specific type of tree, often found in the Mediterranean.

Refining.

The briar is refined into workable blocks known as ebauchons, boiled, and stored in drying sheds for up to 8 months.

Creating.

Artisans carefully select their ebauchons and craft them into unique tobacco pipes to be enjoyed by hobbyists all over the world.

A few words from artisans and customers.

STAY IN TOUCH. —

Stay up to date on everything we do to continue bringing you quality pipes.